If your anchor bolts won't hold, you're not alone. Common issues often stem from incorrect installation or low-quality materials. First, verify you drill the right-sized hole and remove any dust for peak adhesion. If you've installed incorrectly, consider using epoxy to fill oversized holes or switching to a more secure anchor type, like resin anchors. Regularly inspect your anchors for signs of loosening and be ready to re-torque them if needed. With the right techniques and tools, you can stabilize those troublesome bolts. Stick around to discover more strategies for guaranteeing solid anchor installation.

Importance of Proper Installation

When you install anchor bolts, paying attention to proper installation practices is vital for guaranteeing safety and stability. The integrity of your installation hinges on several key factors, starting with drilling the correct size hole. Oversized holes can compromise the anchoring process, often requiring epoxy to secure the installation. Additionally, achieving the minimum setting depth is imperative for all expansion anchors, so double-check your measurements. Utilizing receipt scanning technology can help you maintain accurate records of your installation expenses as well. Incorporating expense tracking apps can also provide valuable insights into your project costs.

Don't forget about dust removal! Accumulated dust in drilled holes can prevent proper seating of anchors, leading to loose or ineffective installations. Take the time to clean out the holes thoroughly before proceeding.

Using high-quality materials is another important aspect; opting for low-quality or offshore anchors can result in installation failures that could jeopardize safety. Furthermore, implementing automation of expense tracking can enhance your operational efficiency, ensuring that resources are allocated effectively.

Regularly evaluating your installation methods and adhering strictly to manufacturer instructions can greatly enhance both the outcomes and longevity of your anchor installations. By prioritizing these proper installation practices, you can mitigate risks and guarantee that your anchor bolts provide the strength and stability you need.

Common Installation Mistakes

Even with proper installation practices in place, mistakes can still occur that jeopardize the effectiveness of your anchor bolts. One common error is drilling multiple holes simultaneously, which can lead to inaccuracies. Instead, drill and install anchors one at a time to maintain precision.

Another significant factor is dust accumulation. After drilling, it's vital to perform dust removal from the holes. If dust remains, it can prevent your anchor from seating correctly, compromising its holding power. Additionally, practicing sustainable methods during installation can contribute to reducing waste and enhancing environmental responsibility. Furthermore, establishing a clear budget can help allocate resources effectively for financial goals during your project.

Additionally, always assess the area before installation. Placing anchors near cracks in concrete can weaken the structural integrity, making it imperative to choose a stable location.

Using the correct size hole is equally important. An incorrect hole size can deform anchor sleeves, leading to potential failure and safety hazards. Always match your drill bit to the recommended specifications for the anchors you're using.

Finally, keep an eye on your installation methods. Regularly monitor for any signs of anchor failure during installation to avoid costly rework and enhance safety. Moreover, ensuring that you are using sustainable packaging solutions during your project can also contribute to a more eco-friendly approach to construction.

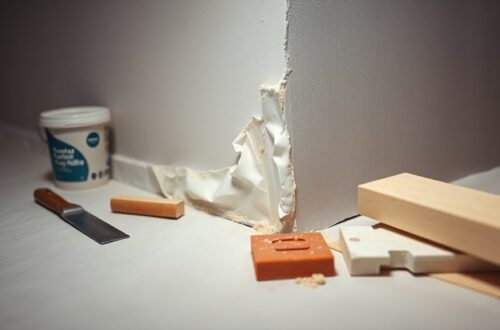

Techniques for Removing Anchors

Removing anchor bolts can be a challenging task, especially when they're stubbornly stuck in place. Start by trying to wrench them loose; persistent effort often pays off as they may eventually pop free.

If that doesn't work, consider using shimming techniques. By inserting shims around the anchor, you can create leverage that helps ease the tension and facilitates extraction. Clear payment terms can also help ensure that any costs associated with the process are understood upfront. Additionally, employing tools like expense tracking tools can assist in managing any expenses related to the removal process.

For particularly problematic anchors, core drilling is an effective method. This minimally destructive technique allows you to extract the bolts while preserving the surrounding concrete, ensuring you don't cause additional damage.

Once you've successfully removed the anchors, it's essential to clean the holes thoroughly. Using compressed air can help clear out debris, enhancing the effectiveness of any epoxy you might apply if you're reinstalling.

After the anchors are out, don't forget to grout the holes to repair any concrete damage. Waiting for the grout to cure is vital, as this will prevent further issues down the line during reinstallation. Additionally, keeping track of payment alerts and reminders during the reinstallation process can help ensure that any associated costs are managed effectively.

Tools for Effective Installation

To achieve a successful anchor installation, having the right tools on hand is essential. Start by selecting an SDS drill for concrete; it's 50% quicker than a combi drill, allowing for efficient hole preparation. Pair this with high-quality drill bits to avoid installation issues.

Remember, after drilling, clean the holes thoroughly with compressed air or a vacuum. This guarantees ideal adhesion for your anchors. Using budgeting tools can help you allocate funds for quality equipment, ensuring better results. Additionally, utilizing AI-driven tools can streamline the shopping process and enhance your overall purchasing experience.

To prevent drilling too shallow or too deep, mark the drill bit with tape to gauge the correct depth. Consistency is key, so focus on drilling one hole at a time to minimize errors.

Utilizing specific installation tools can also enhance your work. For instance, a pry bar can be handy for leverage during bolt extraction, while epoxy designed for anchor bolts can improve the longevity and effectiveness of your installations. Additionally, understanding financial literacy can help you budget for quality tools and materials, ensuring better results in your projects.

With the right tools and techniques in place, you'll set yourself up for success in your anchor installations. Prioritize quality and methodical approaches, and you'll avoid the common pitfalls that lead to anchor failure.

Material Quality and Safety

Choosing high-quality materials for anchor bolts is essential for ensuring safety and stability in your projects. Using low-quality, offshore anchors can greatly compromise safety, leading to potential structural failures. It's critical to select reputable vendors for your anchor materials. Regularly investing in automated investment management can help you allocate funds effectively to ensure quality in your construction materials. Additionally, maintaining a balance between savings and investments is crucial for funding high-quality materials.

Proper installation practices also play an important role in the overall safety of your anchor bolts. Always refer to detailed manufacturer instructions available online to guide you through the process. Pay particular attention to the installation depth; for expansion anchors, insufficient depth can lead to anchor failure under load.

Material quality and installation depth go hand in hand. Regular inspections and strict adherence to manufacturer guidelines can greatly enhance the long-term performance of your anchor bolts, reducing the risk of material failure over time. Additionally, if you're using epoxy products with your anchors, be sure to choose them carefully. Inadequate materials can fail under tension, which can jeopardize safety. Furthermore, investment tracking tools can provide insights that help you assess the financial implications of your construction materials and practices.

Types of Drills to Use

After verifying the quality and proper installation of your anchor bolts, the next step involves selecting the right drill for the job. There are several drill types to evaluate, depending on your project's demands.

For DIY projects, a combi drill is a versatile option. It uses smooth shank drill bits, making it suitable for various tasks, though it mightn't pack the same power as others.

If you're tackling heavy-duty work, especially in concrete, an SDS drill is the way to go. These drills utilize slotted drive shank bits and are designed for efficiency, making them about 50% quicker than combi drills when drilling into tougher materials.

Remember, the hammer function is an essential feature to look for when drilling into concrete, as it provides the impact needed to penetrate dense surfaces effectively.

When selecting your drill type, evaluate the specific requirements of your project. The right choice can greatly affect the efficiency and quality of your work.

Always check the manufacturer's recommendations for the appropriate drill bit diameter to verify compatibility with the anchor type you're using for ideal results.

Drilling Techniques for Success

To guarantee your anchor bolts perform well, you need to focus on achieving the correct hole size and removing any dust or debris.

Measure your drill bit accurately and follow the manufacturer's guidelines for diameter.

Clean the holes thoroughly before installation to prevent any issues with torque or anchor failure.

Correct Hole Size

Getting the correct hole size is essential for a successful anchor bolt installation. If the hole isn't the right diameter, you risk deforming the anchor sleeves, which compromises the overall strength of your installation.

Always refer to the manufacturer's guidelines for the recommended drill bit diameter that matches the specific anchor type you're using.

When drilling, make certain that the drilled hole is deeper than the length of the fixing to provide adequate anchorage for the bolt.

To help prevent drilling too shallow or too deep, use a tape measure on the drill bit to mark the accurate depth. This simple step can save you a lot of frustration down the road.

Dust Removal Techniques

Proper dust removal techniques are essential for guaranteeing a successful anchor bolt installation. Dust accumulation in drilled holes can hinder proper anchor seating, so you must clean holes thoroughly before installation.

Here are some effective dust removal strategies to follow:

- Vacuum Immediately: Use a vacuum with a wand or nozzle attachment right after drilling to remove dust and debris efficiently.

- Compressed Air: If a vacuum isn't available, compressed air can help blow out any remaining dust, guaranteeing clean holes for your anchor installation.

- Assess Drill Bit: Regularly check and maintain your drill bit to guarantee it creates clean holes. A dull bit can generate more debris and increase torque during installation.

- Follow Instructions: Always adhere to manufacturer cleaning instructions. Doing so can greatly improve your chances of a successful anchor installation and reduce the risk of future failures.

Understanding Fixing Types

When it comes to choosing the right anchor bolt, knowing the different fixing types can make all the difference. Expansion anchors are a popular choice because they expand inside the concrete to create a secure hold. However, you need to drill precise holes for ideal installation.

Concrete bolts offer another robust option, using threads that bite into the concrete, typically requiring an 8 mm hole. This makes them ideal for projects that demand durability.

If you're looking for something with a bit more strength, consider resin anchors. These involve a two-part resin that sets around the stud, providing the strongest hold, but require careful handling during installation and curing.

For a more budget-friendly option, sleeve anchors expand into concrete when tightened, offering moderate security, though they may not be as reliable as other types.

Finally, hammer fixings provide a quick installation method by expanding upon hammering into a 6 mm hole, but their strength is limited compared to concrete bolts or resin anchors.

Choosing the right fixing type based on your project's needs can save you time and headaches down the line.

Cost Implications of Anchors

Selecting the right anchor bolt not only involves understanding the different fixing types but also considering the cost implications of each option.

The financial aspects of anchors can greatly impact your project's budget and overall security. Here's a breakdown of common anchor types and their cost implications:

- Expansion Anchors: Typically pricier, these offer enhanced security, making them a solid investment for essential applications.

- Sleeve Anchors: These are budget-friendly and provide a cost-effective solution for moderate security needs in non-essential installations.

- Concrete Bolts: Striking a balance between cost and strength, these are popular for projects requiring reliable anchoring without excessive expenditure.

- Resin Anchors: As the most expensive option, they justify their cost with the highest holding power, ideal for high-stakes environments where safety is paramount.

In essence, the cost of anchors often correlates directly with their strength and permanence.

When selecting anchors, weighing their cost against the level of security they provide is vital to ensuring your project's success without overspending.

Evaluating Installation Permanence

When choosing anchor types, you need to contemplate how permanent you want the installation to be.

Some anchors, like expansion anchors and resin anchors, lock in place and don't allow for easy removal.

Others, such as sleeve anchors, offer some flexibility but may affect the integrity if you keep reinstalling them.

Types of Anchors

Choosing the right anchor type can greatly affect how permanent your installation will be. Understanding the different types available will help you make the best choice for your project's needs.

Here's a quick look at four common anchor types:

- Expansion Anchors: These create a permanent fix within concrete and can't be removed once set. They're perfect for applications where you need a lasting hold.

- Sleeve Anchors: More versatile than expansion anchors, sleeve anchors allow for removal if necessary while still providing a secure grip in various materials.

- Resin Anchors: Though they're the most expensive option, resin anchors offer the strongest fixing available. They cure permanently, guaranteeing long-term stability.

- Concrete Bolts: Typically serving as permanent fixtures, concrete bolts provide reliable strength and resistance to pull-out forces, making them suitable for heavy-duty applications.

When deciding on an anchor, consider the permanence you need.

Expansion and resin anchors are irreversible, while sleeve anchors offer flexibility. By evaluating these options, you'll guarantee your installation meets your long-term goals effectively.

Removal and Reinstallation

Over time, you may find the need to remove and reinstall anchor bolts for various reasons, such as changes in project requirements or wear and tear.

Start the removal process by attempting to wrench the bolts loose, as this method often frees them without causing further damage to the concrete. If they're stuck, consider using shimming techniques to assist with extraction; alternatively, core drilling can be a minimally invasive option that allows for removal while reducing the risk of damaging surrounding material.

Once you've successfully removed the anchor, it's essential to clean the holes with compressed air. This step guarantees ideal adhesion when you apply epoxy during reinstallation.

If you've drilled around problematic anchors, be sure to repair any concrete damage with grout. Allow the grout to cure completely before reinstalling new anchors, as this will help prevent future issues.

Long-term Performance Factors

Permanence is an essential factor in the selection of anchor bolts, especially for projects that require stability and reliability. The type of anchor you choose can greatly impact your installation's long-term performance and your project planning. Here are some aspects to keep in mind:

- Expansion Anchors: These provide a permanent solution once set, making them unsuitable for projects needing flexibility.

- Sleeve Anchors: With the ability for removal, these are versatile and allow for adjustments over time.

- Concrete Bolts: Known for their reliable and long-lasting hold, they serve well in applications where permanence is critical.

- Resin Anchors: Once cured, they become permanent fixtures, offering the strongest fixing but limiting future modifications.

Choosing the right anchor type directly correlates with the anticipated permanence of your installation.

If you foresee the need for removal or adjustments, opt for anchors that provide flexibility. However, if you need a long-lasting hold and stability, you might weigh permanent solutions like concrete or resin anchors.

Balancing these factors will help you achieve the best results for your project.

Security and Strength Comparisons

When it comes to securing fixtures, understanding the differences in security and strength among anchor bolt types is essential.

Expansion anchors are known for providing a strong hold once installed, making them ideal for applications requiring consistent security. However, keep in mind that they can't be removed once set, limiting your options for adjustments later.

Concrete bolts are another reliable choice, favored in high-stress environments for their ability to bite into concrete effectively. They balance strength and flexibility, allowing for removal if needed.

On the other hand, resin anchors offer the strongest hold available, perfect for applications that demand maximum strength, though they come with a higher price tag.

If you're looking for a budget-friendly option, sleeve anchors might fit the bill, but they provide less security compared to expansion anchors and concrete bolts, making them suitable for lighter applications.

Therefore, when selecting an anchor, consider the required security level and strength for your specific project. The right choice will depend on whether you value permanence or flexibility in installation and removal.

User Preferences in Anchors

When choosing anchor bolts, you often balance strength and cost based on your specific project needs.

Some users might opt for concrete bolts for their reliability, while others prefer sleeve anchors to save money.

Your decision ultimately hinges on the application and the level of security you require.

Strength Versus Cost

Choosing the right anchor bolt often boils down to balancing strength and cost. You want a reliable solution that meets your project needs without breaking the bank.

Here's a quick look at some common anchor types to help you decide:

- Concrete Bolts: Often favored for their reliable strength, these bolts are durable but come at a higher cost. Ideal for demanding projects.

- Sleeve Anchors: A budget-friendly option, sleeve anchors provide decent strength for less demanding applications, making them a popular choice when cost is a primary concern.

- Resin Anchors: While the most expensive option, resin anchors excel in maximum holding power, essential for high-stakes environments where structural integrity is critical.

- Expansion Anchors: Chosen for specific uses, these anchors offer secure fixing once installed. However, their removal can be challenging, which might be a drawback for some users.

Ultimately, your choice will depend on the specific requirements of your project, balancing the strength you need against the cost you're willing to incur.

Application-Specific Choices

Your choice of anchor bolts often hinges on the specific demands of your project. For high-stakes applications where security is paramount, concrete bolts are favored for their reliable strength. They guarantee that whatever you're securing stays in place under pressure.

If you're working with a tighter budget but still need moderate security, sleeve anchors offer a cost-effective solution, making them a popular option across various projects.

For situations requiring maximum holding power, resin injection anchors stand out, particularly when you need a permanent and robust fixing solution. They deliver the strength necessary for heavy-duty applications.

Alternatively, if you need an anchor that secures itself immediately upon installation, expansion anchors might be your best bet. Just keep in mind that once set, they can't be removed without damage.

Ultimately, your preferences for anchor types will greatly vary based on project requirements, budget constraints, and the level of security and strength you need. Making application-specific choices will help you achieve the best results while keeping costs manageable.

Always consider your unique needs before selecting the right anchor for the job.

Alternative Solutions for Issues

Finding effective alternative solutions for anchor bolt issues can save time and money. When confronted with problems, it makes sense to explore various methods. Here are some strategies you can implement:

- Use Epoxy for Oversized Holes: If you find oversized holes, consider using epoxy to secure the anchor. This enhances stability and guarantees proper setting depth, which is critical for effective installation.

- Clean Anchor Holes: Dust accumulation can prevent proper seating. Make sure to clean the holes with compressed air before installation for peak performance.

- Fix Loose Bolts: For loose anchor bolts, try wrenching them until they pop free. If that doesn't work, core drilling is a minimally destructive method for extraction and reinstallation.

- Avoid Installation Errors: When drilling, install anchors one at a time. This reduces the likelihood of mistakes and guarantees you adhere to proper techniques.

If you detect anchor failure during installation, regularly assess your methods and choose high-quality anchors from reputable vendors.

Doing so helps prevent liability issues and enhances long-term performance.

Conclusion

So, you thought slapping in some anchor bolts would be a piece of cake? Ironically, those little metal heroes can turn into the villains of your project if installed incorrectly. By avoiding common mistakes and using the right tools, you can guarantee they hold strong. Remember, it's not just about strength but also the quality and permanence of your installation. So, next time, don't rush; give those anchors the attention they deserve! Your walls will thank you.